How to Use a Paint Sprayer: A Practical Guide 2026

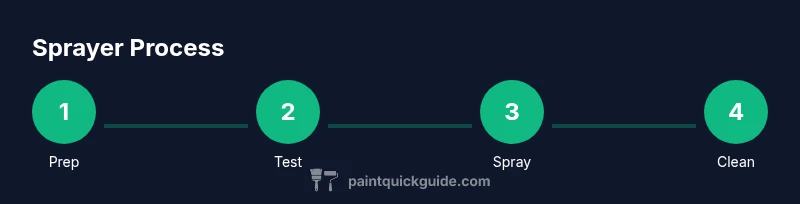

Learn step-by-step how to use a paint sprayer safely and effectively for walls, cabinets, or a car. Includes prep, spray technique, cleanup, and common mistakes to avoid.

According to PaintQuickGuide, by the end of this guide you will know how to use a paint sprayer to achieve smooth, even finishes on walls, furniture, and vehicles while minimizing overspray. You’ll learn essential prep steps, spray technique, and safe cleanup. Before you begin, gather basic supplies, ensure proper ventilation, and wear protective gear to reduce fumes and dust exposure.

Why use a paint sprayer

A paint sprayer is a versatile tool that can dramatically reduce manual brushing or rolling time, especially on large surfaces like walls, ceilings, and exterior façades. For DIY enthusiasts and auto refinishing hobbyists, a sprayer can produce a smoother, more uniform finish with fewer visible brush marks. However, it requires careful preparation, proper technique, and a clean, controlled environment to avoid drips and over-spray. According to PaintQuickGuide, the key to success with any sprayer is balancing speed, distance, and spray pattern to achieve consistent coverage. In this section, we’ll explore the main scenarios where a sprayer shines and what you should expect when you start using one for the first time, including typical learning curves and safety considerations. This early overview sets the stage for practical, hands-on guidance you can apply in real projects, whether you’re refreshing interior walls, refinishing kitchen cabinets, or topping a vehicle with a new coat.

titleOnlyForThisBlockNote():null},

Choosing the right sprayer and setup

Sprayers come in several main configurations, with HVLP (high-volume, low-pressure) models favored for fine finishes and cabinetry, and airless sprayers often preferred for large surfaces and rapid coverage. For most homeowners and DIY auto projects, an HVLP system provides better control, reduced overspray, and a more forgiving spray pattern at modest pressures. When selecting a unit, consider nozzle options, material compatibility, and noise levels. A key decision is whether you need a gravity-feed cup or a pressure-feed system, which affects how you load material and how quickly you can reload during a project. Also, verify the sprayer’s spray fan width and cycle-time to match the surface area you intend to cover. As you plan, keep in mind that paint viscosity, temperature, and humidity will influence performance. PaintQuickGuide recommends testing your setup on cardboard or scrap panel before committing to the actual project so you can calibrate pressure, distance, and pattern without risking a finish you’ll regret.

Tools & Materials

- Paint sprayer (HVLP or airless)(Choose the right model for your project: HVLP for fine finishes, airless for large areas.)

- Replacement nozzles/nozzle tips(Keep the correct size for your material and spray pattern (e.g., 1.0–1.5 mm for latex paints on walls).)

- Protective gear (respirator, safety glasses, gloves)(Lock in good ventilation and protect lungs and eyes.)

- Masking film, painter’s tape, drop cloths(Seal off floors, outlets, and adjacent surfaces.)

- Cart or drop cloths to protect floors(Prevent staining from drips and overspray.)

- Solvent or water-based cleaner(Use appropriate cleaner for your paint and sprayer type.)

- Paint thinner or reducer (as needed)(Used to adjust viscosity according to manufacturer guidelines.)

Steps

Estimated time: 60-120 minutes

- 1

Prepare the workspace

Clear the area and cover floors and furniture. Open windows or use a vent fan to ensure good airflow. Put on protective gear and keep children and pets away from the workspace. A well-prepared space reduces risks and helps you control overspray.

Tip: Double-check that every item near the project is protected before you start spraying. - 2

Mask and protect surrounding surfaces

Apply masking tape and film to trim, outlets, and adjacent walls or furniture. Use drop cloths to catch drips. The goal is to create clean edges and prevent overspray from migrating to unintended areas.

Tip: Secure masking thoroughly; even small gaps can let overspray sneak through. - 3

Test spray and adjust settings

On a scrap panel, test your spray pattern, adjusting distance, speed, and pressure until you see a uniform, feathered edge. Note your optimal distance (commonly 6–12 inches) and ensure your pattern overlaps roughly 50% with each pass.

Tip: Test at low pressure first to avoid painting with a hard, spotty edge. - 4

Thin and mix paint as needed

Follow the paint manufacturer’s guidelines for thinning. Use a viscosity cup if provided, and stir or shake to a consistent, bubble-free mixture. Thinning helps prevent runs and provides a smoother spray.

Tip: Avoid over-thinning; too-thin paint can cause misting and weak coverage. - 5

Apply the first coat with controlled passes

Maintain a steady hand, keep the nozzle perpendicular to the surface, and use overlapping strokes in a consistent motion. Start off the edge and sweep across, releasing the trigger at the end of each pass to avoid heavy build-ups.

Tip: Keep the same speed and distance for even coverage across entire panels. - 6

Let the coat dry and apply additional passes

Check the manufacturer’s dry time and wait accordingly before applying subsequent coats. Apply light, even coats rather than heavy layers to minimize runs and sags.

Tip: Finish with a light tack coat to blend edge lines between coats. - 7

Clean the sprayer and store properly

Flush the system with solvent or water (as appropriate) until the output is clear. Disassemble, dry all parts, and store in a clean, dry place. Regular maintenance extends the life of your sprayer.

Tip: Never leave solvent in the lines between sessions; it can damage seals.

Your Questions Answered

Do I need to thin paint before spraying?

Most paints require thinning to achieve proper atomization and avoid clogging. Always follow the manufacturer’s recommendations for your specific sprayer and material. If you’re unsure, start with a small test sample on scrap and adjust.

Yes, thinning is often necessary. Test on scrap first to avoid waste.

Can I use a paint sprayer indoors?

Indoor spraying is possible with good ventilation and masking, but it’s best for well-ventilated spaces or temporary rooms with proper containment. Protect floors and surrounding surfaces, and consider a controlled environment like a spray booth.

Yes, but you need strong ventilation and masking.

What safety gear should I wear?

Wear a respirator or mask appropriate for solvents, safety glasses, and chemical-resistant gloves. Long-sleeved clothing protects skin, and ensure proper ventilation to manage fumes.

Protect your lungs, eyes, and skin with the right gear.

How do I clean a paint sprayer after use?

Flush with the appropriate solvent or water until the flow runs clear. Disassemble the spray tip, hoses, and filter, then dry and store components in a clean area.

Flush, disassemble, then dry and store safely.

What’s the best distance to hold the sprayer?

Start around 8–12 inches from the surface for even coverage, then adjust based on spray pattern and the material’s viscosity. Keep the nozzle perpendicular to the surface.

About 8–12 inches away for most coatings.

Why is my spray pattern uneven?

Common causes include improper distance, inconsistent speed, clogged nozzle, or incorrect thinning. Re-test on scrap, clean the nozzle, and readjust your technique.

Check distance, speed, and nozzle cleanliness first.

Watch Video

Quick Summary

- Prep and protect: the difference between a good and great finish starts with masking and ventilation

- Test, adjust, and practice on scrap before committing to the project

- Apply even coats with controlled passes to avoid runs and sags

- Clean and maintain the sprayer after every use for longevity