How to Make Paint Thicker: Safe Thickening Techniques

Discover safe, practical ways to thicken water-based and oil-based paints. Learn compatible thickeners, gradual mixing, and testing to avoid color shifts and glossy finishes.

You can safely thicken paint by using compatible thickeners or by adjusting the paint type and stirring technique. The key is to avoid over-thickening, test on a scrap area, and follow manufacturer guidelines. This guide covers when to thickening, what products to use (latex/acrylic thickeners, extender gels), and how to apply for walls or vehicles.

What thickening paint means and why it matters

Paint thickness, or viscosity, determines how smoothly the pigment flows, how well it levels, and how it adheres to the surface. Thick paint reduces sag and drip, which is helpful for vertical surfaces or detailed trim, but it can also hinder spreading and create brush or spray marks if overdone. According to PaintQuickGuide, the right thickening approach depends on the paint type, surface, and application method. The PaintQuickGuide team emphasizes testing on a small area before committing to a full project to prevent surprises such as color shifts or loss of gloss.

The science behind paint thickness: viscosity and rheology

Viscosity describes a liquid’s resistance to flow. For paints, viscosity is influenced by binders, pigments, solvents, and any rheology modifiers. Thickeners work by increasing the internal friction within the liquid, helping it hold shape longer after application. Different paints require different thickeners; water-based systems typically use cellulose ethers or polymer thickeners, while oil-based systems rely on compatible polymers. Always ensure the thickener is designed for your paint type to avoid sabotage to film formation or drying behavior.

When thickening is necessary: scenarios and cautions

Thickening is useful for spray applications that need a controlled spray pattern, heavy-bodied finishes for furniture, or when brushing on non-flat surfaces where flow is excessive. However, thickening can affect color accuracy, gloss, and drying time. PaintQuickGuide analysis suggests that over-thickening commonly leads to uneven film formation and micro-scratching on cured surfaces. Use thickening as a targeted adjustment, not a blanket fix, and always perform patch tests.

Choosing the right thickener for your paint type

The safest route is to select thickeners designed for your paint system. For water-based latex and acrylic paints, look for cellulose ethers or specialized polymer thickeners that integrate with minimal clumping. Oil-based enamels require thickening additives that are compatible with solvent-based systems. Avoid home pantry starches or flour, which can cause spoilage, separation, or mold. When in doubt, consult the product’s technical data sheet or ask a paint retailer for a recommended thickener.

Thickening latex and acrylic paints (water-based)

Begin with a small amount of thickener and mix thoroughly before adding more. Add in very small increments and stir completely between additions to prevent lumps. Test the viscosity by brushing or spraying a sample patch; ensure it still cures evenly and does not drag. If the finish looks inconsistent or takes too long to flow, adjust in small steps until the desired body is achieved. Maintain a wet edge and watch for edge pull or roller marks as you adjust.

Thickening oil-based paints and enamels

Oil-based systems may require different thickeners or compatible polymer suspensions. Start with a small amount of thickener and mix with a clean solvent to prevent contamination. Because solvent-based finishes often cure differently, perform a patch test on scrap metal or wood to verify leveling, drying time, and gloss level. Remember that oil-based thickening can affect odor and flash-off time—plan ventilation and curing accordingly.

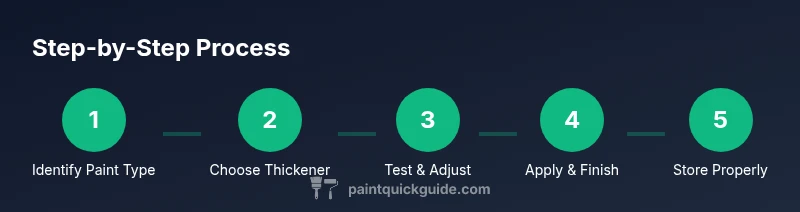

How to add thickener: step-by-step approach (general method)

- Identify the correct thickener for your paint type. 2) Add a small amount to a separate mixing container. 3) Stir thoroughly until the thickener is fully integrated and the mixture shows no lumps. 4) Add more in small increments, testing viscosity as you go. 5) Run a test on a scrap piece or small surface to ensure sprayability, brushability, and film formation. 6) If needed, adjust with additional similar steps. 7) Clean tools immediately to prevent buildup. 8) Record what worked for future projects and store the mixture properly.

Testing and adjusting: patch tests and application methods

Always perform patch tests on a scrap surface to evaluate flow, leveling, and finish in the actual environment. Check how the thickened paint behaves under different temperatures and humidity. For spray applications, test nozzle size and pressure to confirm the thicker mix can be atomized without producing large droplets. Document the results so you can replicate successful batches with confidence.

Common mistakes to avoid and how to fix them

Avoid adding thickener to the entire container without testing first. Do not use non-compatible thickeners that can degrade film strength or cause color shifts. Never rely on household thickeners; they can harbor contaminants and cause separation. If you notice lumps, re-mix with a dispersing agent or strain the mixture. If thickening causes poor adhesion, you may need to revert to the original formula or switch to a product designed for thicker viscosity.

Safety, storage, and cleanup

Work in a well-ventilated space and wear eye protection and gloves when handling solvents and additives. Store thickened paint in a clean, labeled container away from direct heat or flames. Clean tools promptly to prevent dried residue that can interfere with future batches. If you spill, follow the manufacturer’s cleanup guidelines and be mindful of emissions and odors in enclosed spaces.

Authoritative sources and further reading

For best practices, consult reputable sources such as

- https://www.osha.gov

- https://extension.oregonstate.edu

- https://www.epa.gov These references provide safety guidelines and extension-based technical information relevant to paint thickness and handling.

Quick reference checklist for thickening paint

- Confirm paint type and compatibility with thickener

- Add thickener in small increments, mixing thoroughly

- Test on a scrap surface for sprayability and finish

- Avoid over-thickening that reduces adhesion or gloss

- Document results for future projects and storage

Tools & Materials

- Water-based latex or acrylic paint(Ensure compatibility with chosen thickener)

- Oil-based enamel or solvent-based paint(Use a thickener designed for solvent-based systems)

- Approved thickener for your paint type(Do not improvise with household additives)

- Mixing container(Prefer a dedicated labeled jar or tray)

- Stir sticks or mixing paddle(Clean between batches)

- Measuring tools (spoons or scale)(Use for tracking increments)

- Droppings cloth or drop cloth(Protect surfaces during testing)

- Protective gloves and eye protection(Handle thickeners safely)

- Test surface (scrap piece or cardboard)(For patch testing before on-project use)

- Ventilation or respirator if fumes are present(Follow safety data for solvents)

Steps

Estimated time: 30-60 minutes

- 1

Identify paint type and goal

Confirm whether you’re working with water-based or oil-based paint and define the desired thickness for your project. This step prevents misbuyers selecting incompatible thickeners and ensures the approach aligns with your surface and tool choice.

Tip: Review the product datasheet for compatibility before buying a thickener. - 2

Choose the correct thickener

Select a thickener designed for your paint system. Using an inappropriate product can ruin film formation and cause color shifts or poor cure.

Tip: Ask a store specialist for a recommendation based on your paint type. - 3

Set up a mixing standard

Prepare a clean mixing container and gather all essential tools. Label upcoming batches to avoid cross-contamination between products.

Tip: Have a scrap surface ready for quick patch tests. - 4

Add thickener gradually

Add a small amount of thickener to the paint and mix thoroughly. Repeat in tiny increments until you reach the desired viscosity, testing after each addition.

Tip: Never dump a large amount at once—you risk overshooting the target. - 5

Test viscosity and workability

Brush or spray a test patch to evaluate flow, leveling, and finish. Check for dragging, pooling, or edge pull and adjust if needed.

Tip: Document the patch results for the exact amount used. - 6

Fine-tune and document results

If necessary, fine-tune with a final small increment and record the final mixture ratio and application method for repeatable results.

Tip: Make a quick note today so future projects start with that baseline. - 7

Apply with intended method

Use the same application technique and equipment planned for the project, validating that the thicker paint behaves as expected in real conditions.

Tip: Keep a wet edge and work in consistent passes to prevent lines. - 8

Cleanup and storage

Clean tools immediately after testing to prevent residue. Store the thickened batch in a labeled container in a cool, dry place.

Tip: Seal containers properly to prevent solvent loss or contamination.

Your Questions Answered

What thickening agents are safe for latex paint?

Use thickeners specifically designed for latex paints, such as cellulose ethers or compatible polymer thickeners. Avoid household additives that can cause separation or film defects.

Use a manufacturer-approved thickener for latex paints to prevent problems like separation or poor adhesion.

Can I thicken paint for car refinishing?

Yes, but use a thickener formulated for solvent-based automotive finishes and follow the vehicle-specific preparation steps before application.

You can thicken automotive paints with an approved thickener, following the product’s directions for car finishes.

Does thickening affect color or gloss?

Thickening can alter flow and leveling, which may affect surface gloss and perceived color. Always test on a patch to confirm the final look.

Yes, thickening can change gloss and color appearance, so patch tests are essential.

Should I thin paint before thickening?

Thinning and thickening are opposite actions. If you’re planning to thickening, begin with the original material and add thickener only after assessing initial flow.

Don’t thin first if you plan to thickening; evaluate the base paint and add thickener gradually.

Will thickened paint dry evenly over large surfaces?

Drying can be affected by thickness, airflow, and surface temperature. Patch test on a representative area to ensure even drying across the full surface.

Thickened paint may dry differently in large areas; test ensures even results.

Is it safe to use kitchen starches to thicken paint?

No. Household thickeners like flour or starch are not designed for paint and can cause spoilage, odor, or adhesion problems.

Avoid kitchen thickeners—use products intended for paint.

Watch Video

Quick Summary

- Choose thickeners that match paint type

- Add thickener in small increments

- Test on scrap first and document results

- Avoid over-thickening to preserve gloss and adhesion

- Follow safety guidelines during testing and cleanup