How to Make Black Paint: A Practical DIY Guide

A practical guide to making black paint at home using carbon black pigments or color blends, with acrylic and oil-based options, safety tips, and storage guidance.

You can make black paint by using a true black pigment with a compatible binder. For acrylics, disperse pigment powder in acrylic medium to form a paste, then adjust viscosity with water; for oil paints, mix pigment with a drying oil like linseed oil. True black can also be achieved by blending complementary colors, though results vary.

What black paint is and why color control matters

Black paint is more than just the absence of color; it is a carefully engineered suspension of pigment in a binder that forms a solid film as it dries. The perceived depth, opacity, and sheen depend on pigment particle size, lightfastness, and how well the binder encapsulates the pigment particles. In practical terms, choosing the right pigment and binder determines how well the paint covers a surface, how it ages under light, and how consistent the color stays across batches. For homeowners and DIY enthusiasts, understanding these variables helps prevent muddy or uneven blacks that look different on walls, canvases, or metal surfaces. A true black pigment in the right binder will give you a predictable, durable result, whereas a dark mixture of colors can shift with light and over time.

Black is a formulation decision, not just a color choice

Black is most reliably achieved by using high-quality black pigments designed for painting—carbon black or other true blacks—paired with a compatible binder. Some projects benefit from a very deep, matte black, while others require a glossy finish that shines despite the dark tone. The color you end up with should align with your substrate, environment, and the binder system you are using. Always test a small swatch before committing to a full batch to ensure the color, opacity, and finish meet your expectations.

Tools & Materials

- Carbon black pigment (true black)(Fine-ground pigment designed for painting, not printer ink)

- Binder for acrylic base(Acrylic medium or binder suitable for your surface (e.g., acrylic polymer emulsion))

- Binder for oil base(Raw linseed oil or another compatible drying oil)

- Water or solvent as appropriate(Water for acrylic; turpentine or mineral spirits for oil-based paints)

- Mixing tray or glass palette(Clear surface for visual pigment dispersion)

- Palette knife or glass stirring rod(For thorough mixing and dispersion)

- Glass slab or tile (for grinding)(Useful when dispersing pigment before binder addition)

- Muller or blunt-ended tool(To grind pigment into a smooth slurry)

- Scale or measuring spoons(Accurate small-batch measurements)

- Protective gloves and dust mask(Safety first when handling dry pigment)

- Sealable glass jars or paint cans(Store finished paint in airtight containers)

- Tamper-evident label and pen(Record batch details for consistency)

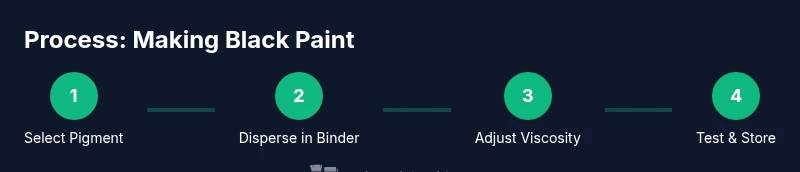

Steps

Estimated time: 60-120 minutes (plus curing time for oil-based paints)

- 1

Set up workspace and safety gear

Clear your area and ventilate. Put on a dust mask, gloves, and eye protection. Secure your jars and keep a cleanup kit handy. This prevents pigment dust from spreading and protects your health during grinding and mixing.

Tip: Ventilation is essential when handling powder pigments to minimize inhalation risk. - 2

Choose pigment and binder

Decide whether you’ll make acrylic or oil-based black. For acrylic, select a high-quality acrylic binder; for oil, select a drying oil like linseed. The choice affects drying time, finish, and durability.

Tip: If unsure, start with carbon black in an acrylic binder for a quick, durable black. - 3

Premix pigment with a small amount of binder to form a slurry

Place carbon black in your mixing tray and add a small amount of binder to create a creamy paste. This helps prevent lumps and ensures even dispersion when you add the rest of the binder.

Tip: Use a glass slab and a Muller for best dispersion. - 4

Disperse pigment thoroughly

Grind the pigment in the binder until you achieve a smooth, uniform slurry free of dry specks. This improves opacity and prevents gritty texture in the final paint.

Tip: Take your time – poor dispersion leads to uneven color and reduced coverage. - 5

Add binder gradually and mix to the final consistency

Slowly blend in the remaining binder while stirring constantly. Stop when the mixture reaches a smooth, paste-like consistency that will spread evenly on a surface.

Tip: Avoid over-thinning; you want opacity, not a wash. - 6

Adjust viscosity with water or solvent

For acrylics, add small amounts of water to reach your desired flow. For oils, use a compatible solvent to adjust workability without breaking the film.

Tip: Add solvent gradually to avoid thinned, translucent film. - 7

Test on scrap material

Apply a small amount to a test panel or scrap. Observe opacity, drying time, and final sheen. Compare with a reference black swatch if available.

Tip: Check both wet and dry appearances; some pigments shift as they dry. - 8

Refine pigment load for depth

If the test looks dull or gray, increase pigment load slightly while maintaining workable viscosity. For true black, a higher pigment-to-binder ratio can improve depth.

Tip: Perform iterative testing in small increments. - 9

Consider sheen and finish

Choose a binder that gives the desired sheen. Matte blacks often use a flatter binder; gloss blacks benefit from higher-resin binders. The finish should suit the surface and lighting.

Tip: If you need a uniform sheen, keep the pigment dispersion consistent across batches. - 10

Make a second batch for consistency

Prepare another batch using the same procedure and compare with the first to ensure color and texture match. Document any adjustments you made.

Tip: Label both batches with date, batch number, and pigment load. - 11

Clean equipment thoroughly

Rinse tools with the appropriate solvent or water, depending on binder. Remove pigment residues to prevent contamination of future colors.

Tip: Proper cleaning extends the life of your gear and preserves color integrity. - 12

Store and document

Seal containers tightly and store away from direct sunlight. Record the pigment load, binder ratio, and any notes for future reference.

Tip: A simple batch log helps you reproduce the same color later.

Your Questions Answered

Can I make black paint by mixing other colors?

Mixing primary colors or complementary colors can yield a deep dark color, but it rarely achieves true black consistently. Pigment-based black provides more reliable coverage and aging characteristics.

Mixing colors can make a dark color, but true black from a pigment is usually more reliable for consistency and longevity.

Is it safe to grind pigment powders by hand?

Grinding pigments should be done with appropriate PPE and in a ventilated area to minimize inhalation. Use a mortar and pestle or a glass slab with a muller, and avoid creating a fine dust cloud.

Yes, but wear a mask and work slowly in a ventilated space to avoid inhaling pigment dust.

What bases work best for black paint?

Acrylic binders are versatile and quick-drying for indoor use, while oil-based binders offer richer gloss and longevity for traditional finishes. Surface compatibility and drying time should guide your choice.

Acrylics are versatile and fast-drying; oils give richer gloss and longer life.

How long does homemade black paint last?

Shelf life depends on binder and storage. Seal containers tightly and store away from heat and sunlight; oil-based mixes can cure over weeks to months, while acrylics typically remain usable longer if kept airtight.

Shelf life varies by binder; keep it sealed and cool for best results.

Can I use household products to make black paint?

Avoid substitutes that aren’t designed for paints, as they can affect adhesion, odor, and safety. Use dedicated pigments and binders to ensure performance and safety.

It's best to stick with proper pigments and binders rather than household items.

Do I need to seal homemade black paint?

Sealing is recommended if you need chemical or UV resistance or to reduce dusting. Choose a compatible varnish or clear coat based on whether you made acrylic or oil paint.

Sealing helps with durability and finish, choose a compatible varnish.

Watch Video

Quick Summary

- Choose true black pigments for depth and stability.

- Binder choice determines finish and aging characteristics.

- Dispersion quality drives opacity and uniform color.

- Test in small batches before committing to large projects.

- Document batches for repeatable results.