How to Fix Paint Chips on a Car: A Practical DIY Guide

Learn a step-by-step method to repair car paint chips at home with color matching, masking, and clear-coat finishing for a durable, near-seamless repair.

You're looking to stop rust and restore your car's finish by fixing paint chips. This quick guide outlines a practical, cost-conscious approach that works for common chip sizes. You'll learn prep, color matching, and sealing, plus safe handling tips. By following these steps, most chips can be repaired at home without professional equipment.

Prep the Chip Area

According to PaintQuickGuide, proper prep sets the stage for a durable repair. Begin by washing the vehicle around the chip with mild soap and water to remove dirt. Dry thoroughly, then inspect the chip edges for rust or loose material. If rust is present, treat with a rust converter before continuing. Mask surrounding panels with painter's tape and newspaper to protect adjacent paint. This initial step minimizes edge chipping and helps the color layer adhere smoothly. Safety is essential; wear gloves and eye protection when handling solvents and paints. Remember, a clean, dry surface is the foundation of a long-lasting fix.

Understanding Chip Types and Color Matching

Paint chips vary from tiny surface nicks to deeper gouges that expose metal. Your color-match approach depends on the chip size and location. For small chips, touch-up paint or pens can work, while deeper areas may require filling compounds and base coats. Color matching is critical: even a small shade mismatch can stand out under sunlight. Test paint on a hidden panel or a disposable metal leaf before applying to the car. PaintQuickGuide analysis shows that the most convincing repairs come from accurate color matching and controlled application indoors at moderate temperatures.

Materials You’ll Need (Tools and Consumables)

Before you start, gather the essentials. You’ll need masking supplies, the color-matched touch-up paint, a clear coat, filler if needed, fine sandpaper, and degreasing solvent. Keep a clean workspace and organize the tools so you can reach them without leaving gaps in your process. Using dedicated automotive materials improves longevity and finish quality. Always verify colors against the car's code before painting to avoid repeated fixes.

Surface Preparation: Cleaning, Degreasing, and Masking

Deep-clean the chip area with isopropyl alcohol or a dedicated prep solvent, wiping with a lint-free microfiber cloth. Avoid water-based cleaners that can leave residues. Lightly sand the chip edges with very fine paper (1500–2000 grit) to smooth any raised edges, then wipe again. Mask the surrounding area with tape to prevent overspray and ensure crisp lines. The goal is a clean, flat surface that accepts paint evenly and blends with the existing finish.

Color Matching Tests and Small-Scale Mixing

Match the car’s color code using a controlled lighting setup; view under daylight or a bright shop light to avoid misjudges. If you’re between shades, mix a tiny amount on a white disposable palette and test on a metal test panel or a folded piece of clear plastic. Allow the color to dry fully before comparing. This step reduces mismatch when you apply the base color to the chip and increases the chance of a seamless blend.

Applying Base Coat and Filler

If the chip depth calls for it, apply a thin layer of automotive filler or glaze to level the recess. Let it cure as directed on the product label, typically 5–15 minutes for quick-dry fillers. Lightly sand again to provide a smooth, flush surface. Then apply a small amount of color-matched base coat with thin, even coats, allowing each layer to dry for 5–10 minutes before the next. The key is building coverage gradually to avoid runs while meeting the chip’s depth.

Sealing with Clear Coat and Blending Edges

Once the base coat is dry, apply a clear coat in several ultra-thin passes to create gloss and protect the color layer. Build the coat slowly, watching for runs; if needed, the final coat should be slightly wetter to help blend into the surrounding paint. After the clear coats dry, level the finish with a very light, fine abrasive (2000–3000 grit) and a polishing compound to blend the repaired area with the rest of the panel. This step is critical for a near-invisible repair.

Curing, Polishing, and Maintenance

Allow the repair to cure fully before washing or exposing it to harsh conditions. Depending on product specs and climate, cure times can range from 24 hours to several days for full hardness. After curing, polish the area with a gentle automotive polish to restore shine and knock down any micro-marring. Apply wax after a few days to protect the finish. Regular maintenance reduces visibility of the repair and extends the life of the fix.

Common Mistakes and Best Practices

Common mistakes include using overly thick coats, skipping masking, and rushing curing times. Work in a clean, dust-free environment and prefer thin layers over heavy pours. Always test color before applying to the car and keep backup color for touch-ups. By following best practices, you’ll achieve a durable, aesthetically pleasing repair even for first-timers.

Tools & Materials

- Isopropyl alcohol (70-90%)(For degreasing surface and prepping.)

- Lint-free microfiber cloths(2–3 cloths for cleaning and drying.)

- Fine-grit sandpaper (1500-2000 grit)(Smooths edges without deep scratches.)

- Automotive filler or glaze(Use only if the chip is deep.)

- Touch-up paint (color-matched)(Primary color for base layer.)

- Automotive clear coat(Seal and protect the color layer.)

- Masking tape and paper(Protect surrounding areas.)

- Small mixing cups and toothpicks(For color testing and mixing small amounts.)

- Sharp detailing brushes or paint pens(For precise base and edge work.)

- Safety gear (gloves, eye protection)(Personal protection.)

- Disposable test panels(Optional for color testing.)

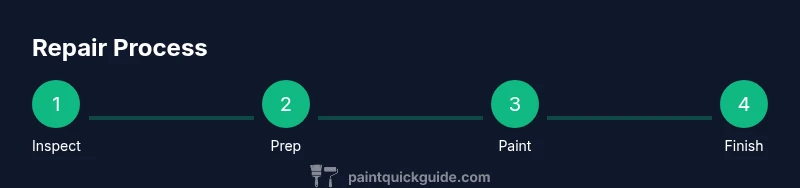

Steps

Estimated time: 60-90 minutes active work; 24+ hours full cure

- 1

Inspect the chip and prep the area

Examine the chip to determine depth and whether rust is present. Decide whether you can repair with a surface touch-up or need filler. Gather tools and ensure the surrounding area is clean.

Tip: Wear gloves and eye protection; plan your coat sequence. - 2

Clean and degrease the chip area

Wash the area with mild soap, rinse, and dry. Degrease with isopropyl alcohol to remove oils that hinder adhesion.

Tip: Use lint-free cloths and avoid leaving residue. - 3

Mask surrounding panels

Apply masking tape around the chip to protect adjacent paint from overspray. Use paper to cover larger areas.

Tip: Keep your mask edges tight for a clean line. - 4

Lightly sand the chip edges

Gently smooth raised edges with 1500–2000 grit sandpaper until flush with surrounding paint.

Tip: Do not sand through existing clear coat. - 5

Apply filler if needed

If the recess is deep, apply a thin layer of automotive filler. Let cure 5–15 minutes per product instructions.

Tip: Build in very thin layers to prevent air pockets. - 6

Test color and mix if necessary

Test color on a disposable panel; adjust shade with tiny color drops until matching. Discuss shade under daylight.

Tip: Record the ratio of mix for future touch-ups. - 7

Apply base color in thin coats

Apply the base color in several light coats, allowing 5–10 minutes between coats. Build coverage to match surrounding paint without pooling.

Tip: Keep strokes even and avoid over-wetting the area. - 8

Seal with clear coat and blend

Brush or spray clear coat in multiple ultra-thin passes. Let each layer dry before the next; finish with a final wet coat for blending.

Tip: A slightly wetter final coat helps feather edges. - 9

Cure, polish, and assess

Allow full cure (typically 24 hours). Polish lightly to blend the repaired zone with surrounding paint and apply wax after curing.

Tip: Don’t wash the area for 24 hours.

Your Questions Answered

Is it safe to fix paint chips at home, or should I hire a pro?

For small chips on flat panels, a careful DIY repair is usually safe with proper materials and ventilation. Large chips, rust, or curved surfaces may require a pro to achieve a durable finish.

DIY repair works for small chips on flat areas; bigger or rusty chips are best handled by a pro.

Can I use regular nail polish for chips?

Nail polish is not designed for automotive finishes. It can fade, peel, or react with clear coats. Use automotive touch-up paint matched to your color for best results.

Nail polish isn’t recommended for car paint chips; use automotive touch-up paint.

Will the repair be a perfect color match?

Color matching is very close but rarely perfect. The surrounding gloss, sun exposure, and blending technique influence final appearance. Test on a spare panel before applying to the car.

Color matching is usually close but not perfect; test first.

How long should I wait before polishing after applying clear coat?

Wait for the clear coat to cure according to product instructions, typically 24 hours. A longer cure improves hardness and shine.

Let the clear coat cure for about 24 hours before polishing.

What if the chip is near a seam or edge?

Chips near seams or edges are harder to blend. You may need a professional spray or color-matching service for a seamless result.

Chips near seams are tricky; consider a pro for best blend.

Should I use a spray can or brush for the base coat?

Spray cans give a finer, more even layer but require masking and ventilation. Brushes are easier for tiny chips. Choose based on chip size and your setup.

Spray gives even coverage; brush works for small chips.

Watch Video

Quick Summary

- Prepare thoroughly before painting to ensure adhesion.

- Accurate color matching reduces visible repair lines.

- Use thin coats and allow curing between steps.

- Protect surrounding panels to maintain overall finish.

- Polish and wax after full cure for longevity and gloss.